TRADITION

COMPANY HISTORY

„Power Engineering S.A.” ( operating until the end of 2009 under the name Zakłady Produkcyjno-Remontowe Enegetyki Poznań „Energetyka Czerwonak” S.A.) was established in 1951 as a power engineering repair unit for the western region of Poland.

During over 70 years, our engineers and specialists have repaired and renovated ( including major repairs) hundreds of power devices: transformers, generators, engines and turbines.

For over 20 years, as the only company in Poland, we produce radiators for power transformers in a full range with valves for customers in the country and abroad.

We implement modern solutions that increase the quality of our products as well as increase production capabilities, while respecting the natural environment and the safety of our emplyees. Using the experience and knowledge gained in the past, we boldly look into the future ready for new challanges.

Conquering the World

We have made many different devices and constructions for customers all over the world, from specialist low NOx burners to large-size air heaters, and last time substrate tanks for agricultural biogas plants and other plant components.

Experience and cooperation

Over the years, working with Politechnika Poznańska, we have raised the qualifications of our emoplyees and gained experience that allows us today to undertake the most diffcult tasks.

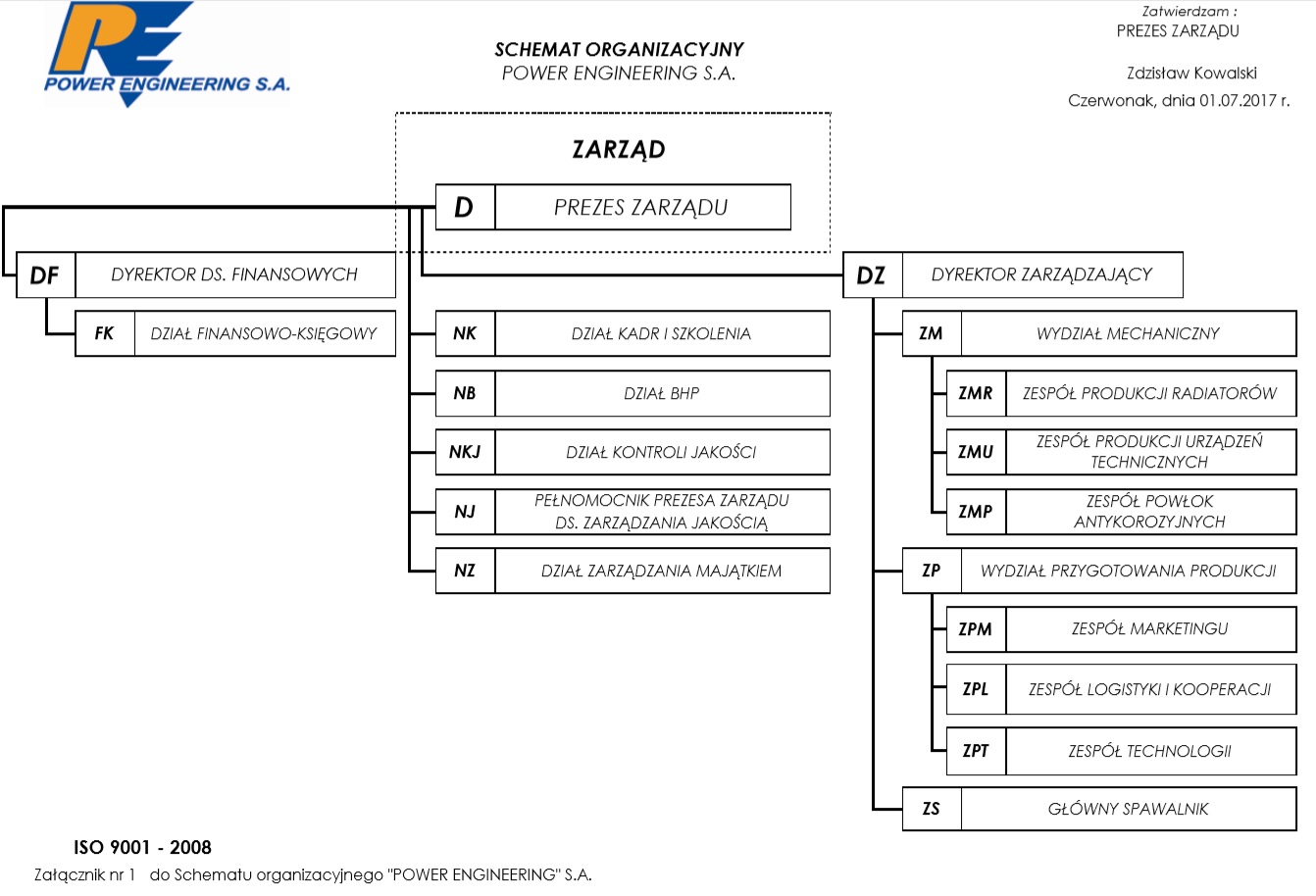

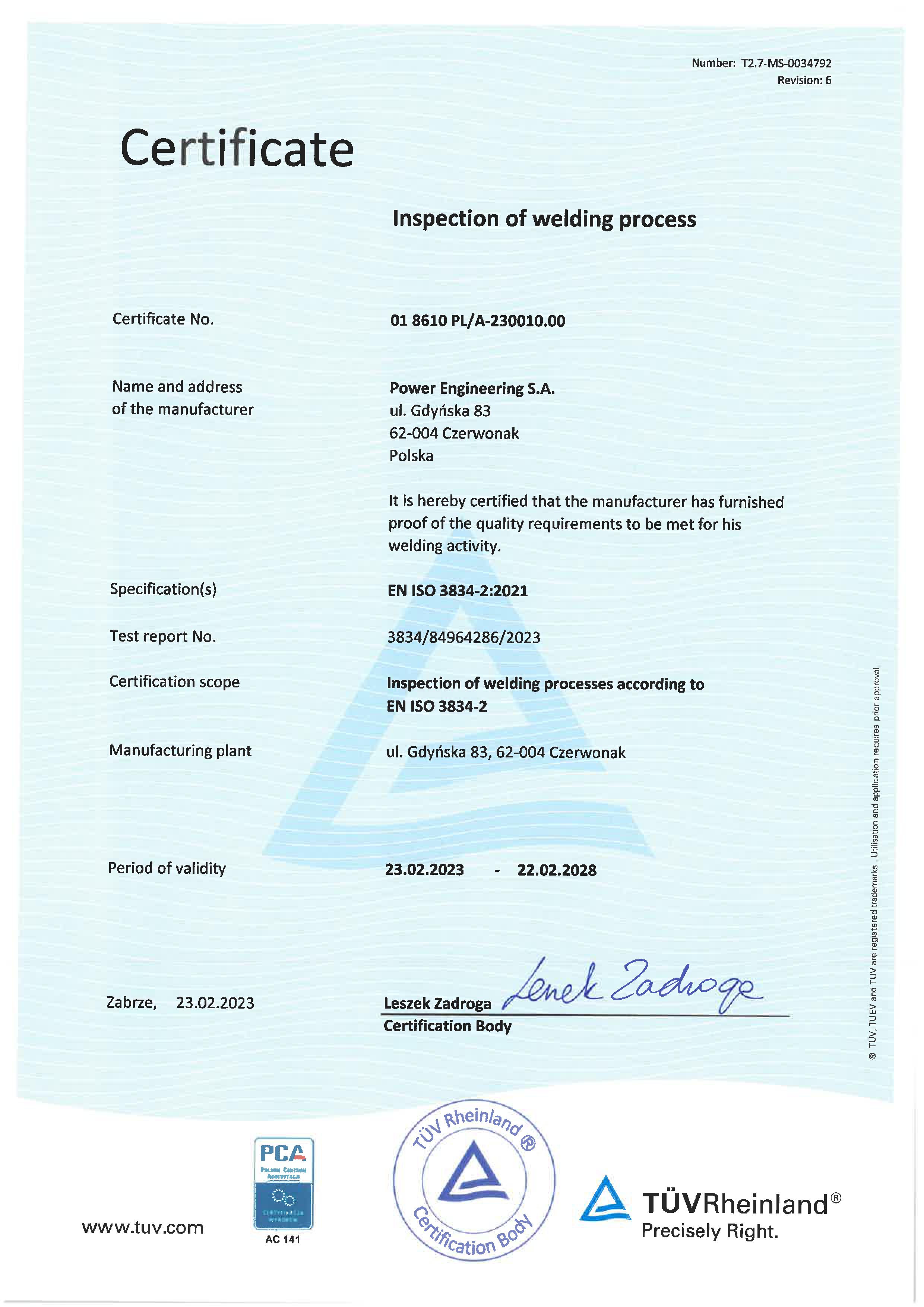

We focus on quality

We focus on the quality of our products and services, provided by the PN-EN ISO 9001:2015-10 system and the adopted Quality Policy.

QUALITY

Products

Choose the categories that interest you from the catalog below.

Technical devices production

- low NOx burners for power station boilers feed by popular fuel, like coal, oil and gas In several configurations and models

- ash reclaimers

- ash conveyors

- transformer tanks

- emission reduction equipment

- piping and ducting

- dampers, coal chutes, sifters

- coal mills, separators, classifiers

- water and gas valve bodies

- boiler constructions, carburizing systems

- electrostatic precipitator constructions and air preheater constructions

- exhaust gas, air and mixtures ducting

- coal feeders, furmance hoppers

- separators, turbulators

- radial and circular sealing systems of air preheaters

- welded building constructions

- valves for transformers

- photocell controlled automatic cutting of any shapes (oxy-acetylen, plasma arc)

- guillotine shears cutting

- cold and hot shaping (eccentric, friction and hydraulic press),

- rolling cones and cylinders

- plates shaping (folding press)

- drilling (multiradial drilling machines, pillar drillers)

- MMA-electrical welding, MAG–welding and TIG-welding

- cutting and shaping on the eccentric press, tonnage 160 tons

- turning (universal lathes, boring lathes, NC lathes)

- gear cutting (gear lobbing machines)

Corrosion protection

The company has a modern blast chamber with floor scraper, abrasive recirculation system and a separator chamber (dimensions: 10x6x6 meters), where the elements are prepared for painting. Application of coatings is in the paint-drying cabin measuring 20x6x6 meters. Both facilities meet all standards for the reduction of harmful emissions into the environment and provide high quality anti-corrosion coatings.

Diagnostics

Second degree metal science laboratory

- radiographic examination RT

- ultrasonic testing UT

- magnetic particle inspection MT

- liquid penetrant examination PT

- static tensile test of steel products and welded joints

- impact testing of steel products and welded joints

- static bending test of welded joints

- Hardness measurement using Rockwell i Vickers methods

- Macroscopic examination

You can find more detailed information in our catalog. Click the button below to download the catalog or check our latest projects.